Affordable Solutions for Your Hobbies

Explore the range of services we offer to hobbyists, designed to provide expert assistance for your personal projects.

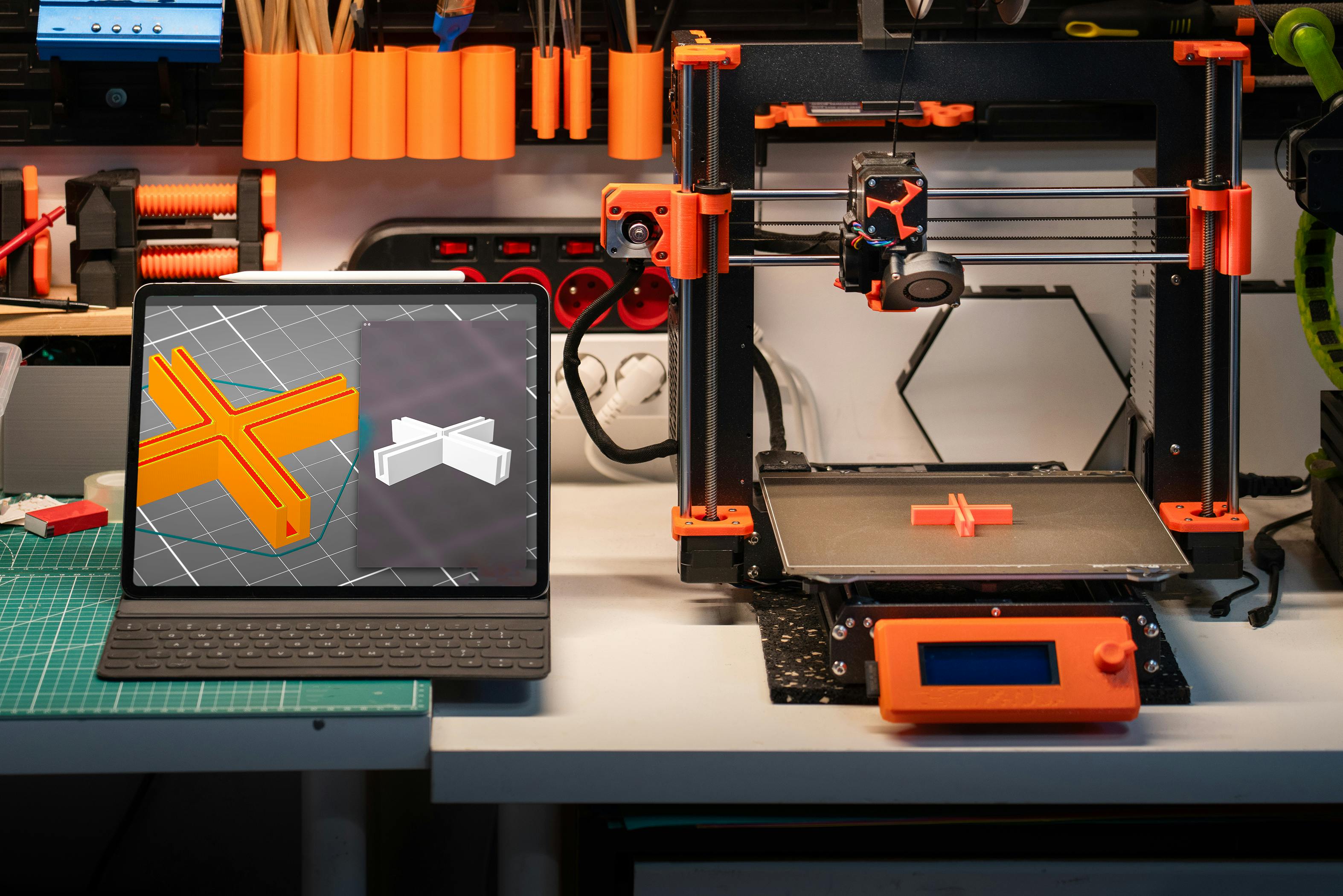

What is 3D printing?

We provide both FDM and resin printing solutions to meet the needs of your hobby project with precision and reliability.

Collapsible content

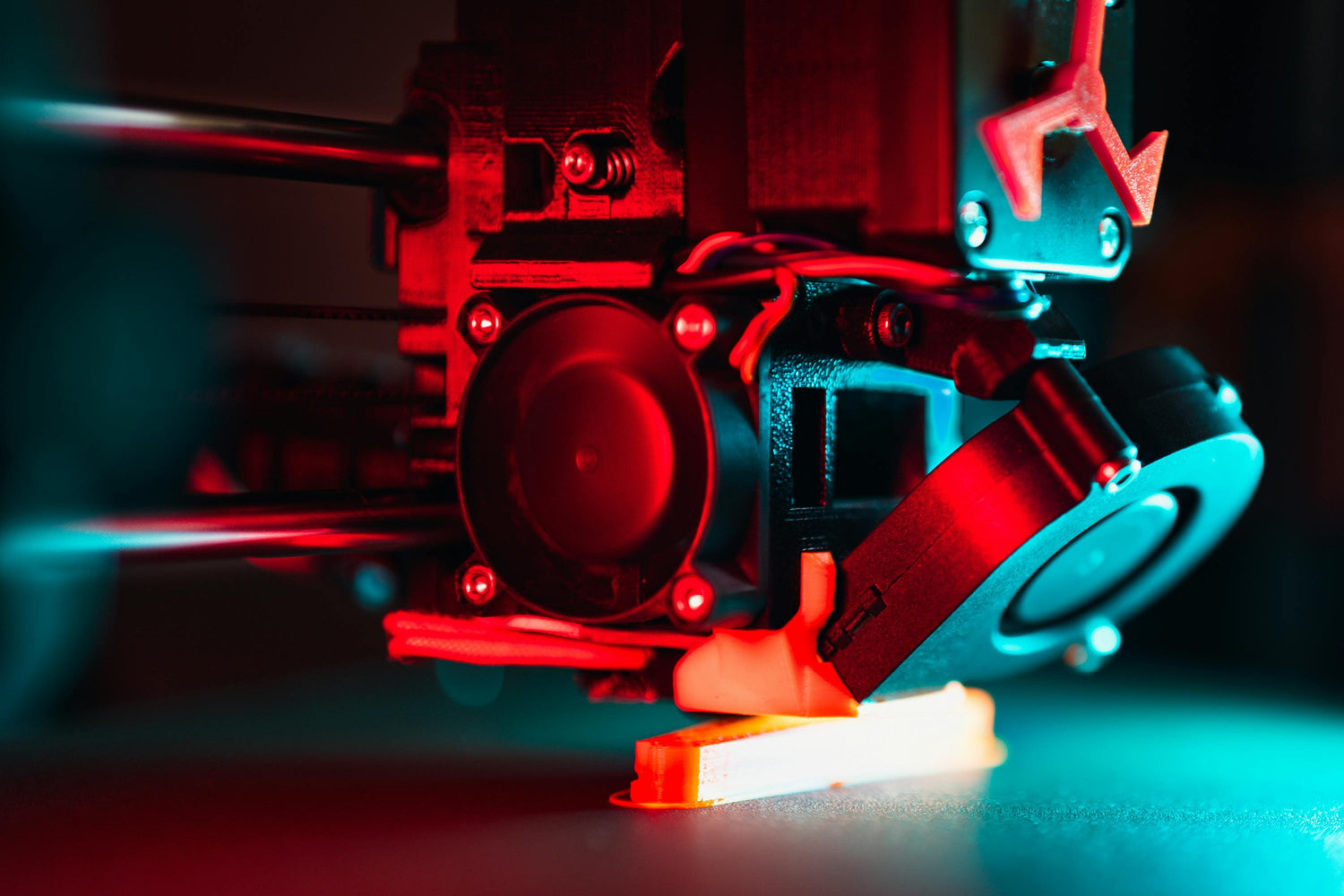

About FDM printing

Fused Deposition Modeling (FDM) is a 3D printing technology that builds parts layer by layer by extruding heated thermoplastic filament. It is known for its affordability, versatility, and ability to produce durable prototypes and functional components. FDM is widely used in engineering, manufacturing, and product development due to its efficiency and material options.

About resin printing

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), uses liquid photopolymer resin cured by a light source to create highly detailed and smooth parts. It is ideal for applications requiring precision, such as prototypes, jewelry, dental models, and miniatures. Resin printing offers excellent surface finish and fine feature resolution, making it a popular choice for high-quality, intricate designs.

What materials can be printed?

We offer a selection of high-quality materials for both FDM and resin printing to meet diverse project requirements.

FDM Materials:

- Polylactic Acid (PLA)

- Polyethylene Terephthalate Glycol (PETG)

- PolyMaker PolyLite (ASA)

- Mitsubishi DuraBio Polycarbonate (PC)

Resin Materials:

- SirayaTech Navy Grey

If you require a specific material not listed above, please contact us—we may be able to accommodate your needs.

How to work with us

Working with us is super straight forward. Simply send us an .STL or .STEP (.STP) file of your part and we'll reply with a quote which includes printing, post processing and delivery.

Use the contact form at the end of this page to get started.

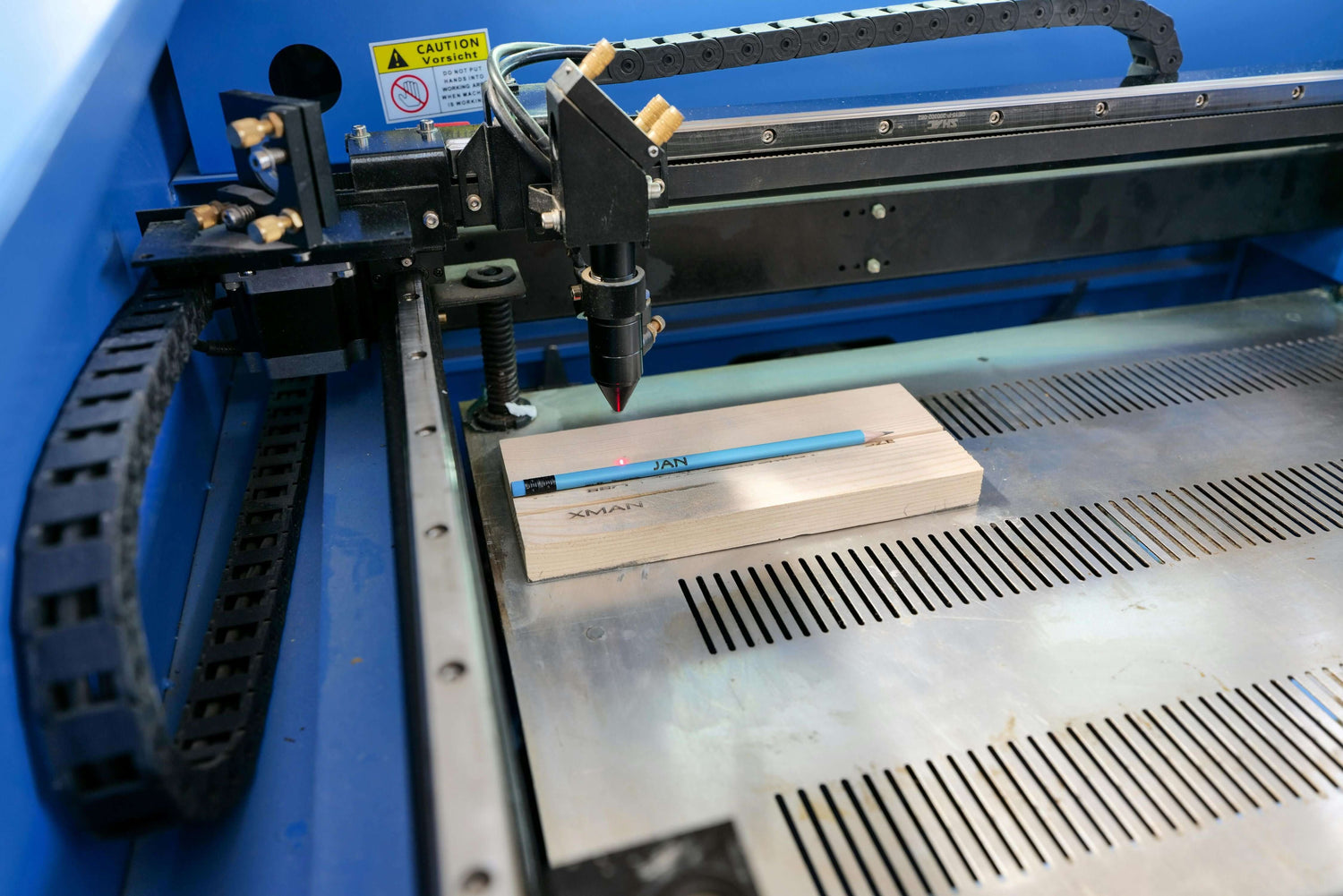

Laser cutting and engraving

We own a 500 x 700 mm CO2 60W laser cutter that can work with a variety of materials.

Collapsible content

About laser cutting & engraving

CO₂ laser cutting and engraving use a high-powered carbon dioxide laser to precisely cut or etch materials. In cutting, the laser beam vaporises the material along a defined path, producing clean, smooth edges. Engraving, on the other hand, removes the surface layer to create detailed designs, text, or patterns without cutting through the material.

CO₂ lasers are widely used for working with wood, acrylic, leather, cardboard, and more.

What materials do we use?

We offer a selection of material types but the colour and style is up to you.

Cuttable Materials

- MDF upto 6mm (veneered or otherwise)

- Plywood upto 6mm

- Acrylic upto 6mm

- Card & Cardboard

- Cork

- Leather

Engravable materials

- MDF

- Plywood

- Card & Cardboard

- Cork

- Leather

- Slate

If you require a specific material not listed above, please contact us—we may be able to accommodate your needs.

How to work with us

We support a variety of file formats for laser cutting, whether you're starting with a simple image or a detailed 3D model that you want you want splitting. To discuss your project, please use the contact form below to provide the details, and we will get in touch to assist you.

We use a variety of softwares to accomplish amazing results such as Inventor, AutoCAD, Illustrator, Photoshop and Lightburn.

Connect, Create, Innovate

Please get in touch if you need any assistance or advice, we are always happy to help!

Please allow us up to 48 hours to get back to you.